China's Leading Rubber Belt Manufacturer Since 1999

IATF 16949 Certified | 130+ Rubber Compounds | Export to 100+ Countries

Longyi Rubber Products Factory

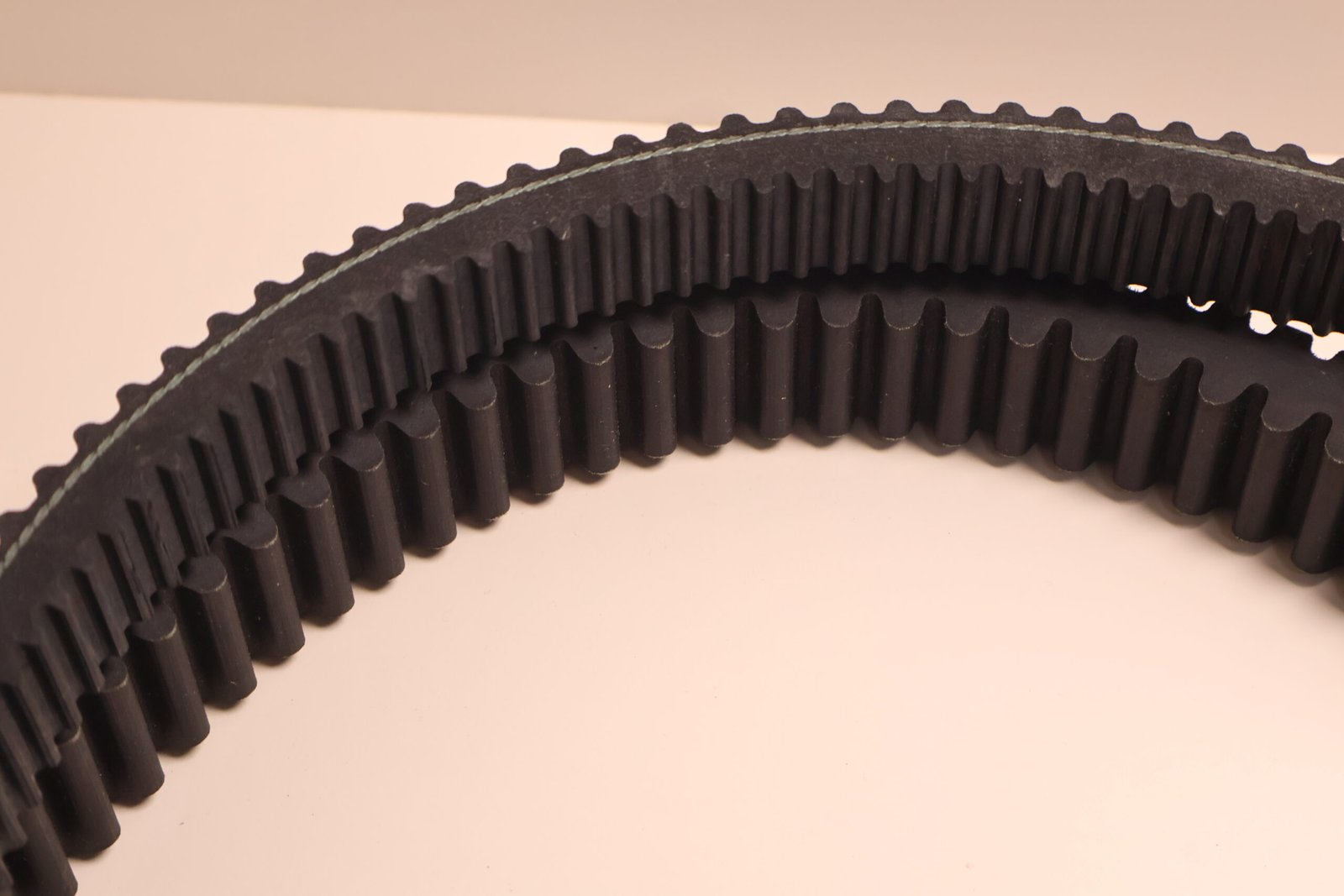

Has V-ribbed belt, V-belt, Timing belt and Cogged belt,Wrapped belt.

Company vision

To be the most respected enterprise in society and create a world-class enterprise.

IATF 16949 Certified

ISO 9001 / 14001 / 45001

Manufacturing Since 1999

Export to 100+ Countries

130+ Rubber Compounds

Our Rubber Belt Product Range

Five major product lines covering automotive, industrial, agricultural, and specialty applications.

Explore Our Featured Products

Company profile

Established in 1999, our factory is a leading producer of rubber belts, including multi-wedge, V-belts, timing belts, automotive belts, and belts for industrial and agricultural use. Spanning 50 acres with over 200 employees, we have modern production facilities ensuring high-quality output. Our annual production value reaches 100 million RMB, highlighting our strong market presence. We are committed to innovation and quality, catering to diverse needs in both domestic and international markets.

Why Choose LYBELT as Your Rubber Belt Supplier?

Longyi Rubber Products Factory (LYBELT) is one of China’s top 10 automotive parts enterprises, specializing in the manufacturing of high-quality rubber belts for automotive, industrial, agricultural, and specialty applications.

Since our founding in 1999, we have developed more than 130 proprietary rubber belt formulations covering tens of thousands of belt specifications. Our products are exported to more than 100 countries across North America, Europe, the Middle East, Southeast Asia, and Australia, serving automotive parts distributors, industrial equipment suppliers, agricultural machinery dealers, and OEM manufacturers worldwide.

IATF 16949 Certified | Automotive-grade quality management system. Every belt is traceable from raw material to finished product.

130+ Rubber Formulations | EPDM, CR, HNBR, NBR, NR, FKM — engineered for any operating environment from -40°C to +200°C.

Aviation-Grade Discipline | 2018 aviation product certification. Aerospace-level quality control embedded in every product line.

Global Export Experience | 80%+ export ratio to 100+ countries. We understand international standards, packaging, and logistics.

Enterprise purpose

sincere cooperation, Based on integrity

Company vision

To be the most respected enterprise in society and create a world-class enterprise

Company mission

to increase more income for employees and make greater contributions to society

Longyi spirit

lean, hard work, unity and cooperation, absolute loyalty to the enterprise

The development of rubber belt needs to consider the following aspects:

- Material selection: Select suitable rubber materials according to the use environment and needs, such as natural rubber, chloroprene, butadiene, EPDM and so on.

- Belt design: Consider the impact of the size, shape, pattern and other factors on the performance of the belt.

- Production process: Optimize the production process, improve production efficiency and reduce costs.

- Performance test: the rubber belt tensile, wear resistance, corrosion resistance and other performance test to ensure product quality.

- Environmental protection requirements: Consider whether the production and disposal process of rubber belt meets environmental protection requirements.

- Market demand: Investigate market demand, understand customer demand, and develop competitive products.

- Technological innovation: pay attention to industry dynamics, introduce new technologies and new materials, and improve the performance of rubber belts.

The maintenance method of rubber belt has the following points:

- Regular inspection: regularly check the wear, aging and tightness of the belt, find problems in time and deal with them.

- Cleaning: Clean the belt regularly to keep its surface clean and avoid the accumulation of dust and dirt.

- Adjust the tension: regularly check and adjust the tension of the belt to keep it within the appropriate range.

- Replacement: When the belt is worn, aged or damaged, a new belt should be replaced in time.

- Avoid contact with oil: try to avoid belt contact with oil, so as not to affect its service life.

- Avoid direct sunlight: try to avoid direct sunlight belt, so as not to accelerate its aging.

OEM & ODM Custom Belt Manufacturing

We manufacture rubber belts under private labels for distributors worldwide. Whether you need specification matching, custom compound development, or complete product design — we’re your technical manufacturing partner.

OEM Manufacturing

ODM Development

Private Label

Quality Certifications & Standards

Quality isn’t something we talk about — it’s something we prove. Our facility holds the most demanding certifications in the rubber belt industry.

IATF 16949

ISO 9001

ISO 14001

ISO 45001

Aviation Cert

Industry Insights & Technical Resources

Xingtai Valley Blue Technology Co., Ltd. | Comprehensive Guide to Selecting & Maintaining Rubber Power Transmission Belts

Xingtai Valley Blue Technology Co., Ltd. | Comprehensive Guide to Selecting & Maintaining Rubber Power Transmission Belts Intended Audience: Equipment engineers, procurement teams, after-sales, and

Longyi Rubber Products Factory: Upgraded Timing Belts with Teflon Material for Automotive Applications

Longyi Rubber Products Factory: Upgraded Timing Belts with Teflon Material for Automotive Applications In the modern automotive industry, Timing Belts are an essential component of

What Makes a Quality Rubber Belt: An In-depth Look at Materials and Manufacturing Processes

The humble rubber belt, an essential part of many machines ranging from vehicles to agricultural equipment, is often overlooked in its importance. However, the quality

Ready to Find Your Ideal Rubber Belt Solution?

Contact our technical team for a free consultation. We’ll help you select the right belt type, material, and specifications for your application.